Thermal mass flow meters are perfectly suited for measuring clean, dry compressed air and inert gases, where accuracy on smaller pipe sizing is important. Compressed Air Alliance offers two types of thermal mass flow meters – inline (or in-line) flow meter and insertion flow meter.

Inline Flow Meters

- Inline flow sensors include a section of pipe as part of the flow meter. Threaded pipe sections are available from DN15 to DN50. Flange pipe sections are available from DN15 to DN80.

- Inline flow meters are best suited to permanent installations as you will need to cut out a section of pipe to install the flow meter. You will also need to turn off compressed air while you install the inline flow meter.

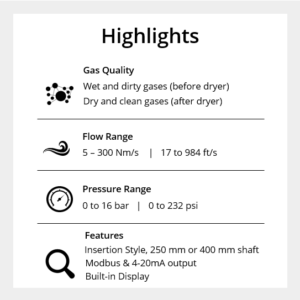

Insertion flow meters

- Insertion flow sensors are inserted into the pipe through a valve. They can be inserted under pressure so you don’t need to turn off your compressed air system during installation.

- Insertion flow meters are best used for permanent and temporary installations.

- For information on the Insertion flow meter, refer to the Thermal Mass Flow Meter page.

Both of Compressed Air Alliance’s thermal mass flow meters (inline and insertion style) have a streamlined sensor tip which ensures minimal impact on gas flow while maintaining accuracy over a wide flow range.

Features of Inline Flow Meters

- Inline type sensor

- Thermal mass technology, independent of temperature and pressure change

- Measurement range: 0.1 to 250 Nm/s (820 ft/s)

- Integrated temperature sensor

- Accuracy of ±1.5% reading, ±0.3% full scale (high accuracy ±1% available on request)

- Modbus RTU and 4 to 20 mA + Pulse outputs

- 2.8″ ultra-wide viewing angle LCD touch screen

- Data logging with up to 10,000,000 recording points

- Suitable for pipes from DN15 – DN80 provided minimum velocity is maintained

- Measures standard flow, mass flow, consumption and temperature

- 12 month warranty

- Ultra-wide 1:2500 turndown ratio

- Full digital signal processing for higher precision and better stability

- Integrated gas temperature measurement

- No moving parts, low pressure drop

- Full electrical isolation to filter out disturbances

- Stable signals

- Vibration resistant

Inline Flow Meter comes with:

- M12 connector (data cable optional)

- Calibration certificate

- User Manual

- 12 month warranty

Inline Flow Meter Options

- Pressure: 1.6 MPa (16 bar) or 4.0 MPa (40 bar)

- Pipe Connection: Flange (DIN) or R-Thread

- Pipe Section: DN15, DN20, DN25, DN32, DN40, DN50, DN65 or DN80

- Gas Types: Air, Argon, Carbon Dioxide, Helium, Hydrogen, Natural Gas, Nitrogen, Nitrous Oxide, Oxygen

Important

The sensor must be installed (i) in dry gas, (ii) at 90° to the pipe and (iii) away from bends, edges, seams, changes in pipe size and other obstructions,

Incorrect wiring or installation can give false readings, damage the sensor and void the warranty. If you aren’t sure how to install or wire the sensor, please contact us. Full installation and wiring instructions are available in the User Manual.

Warranty & Calibration

12 month warranty

Calibration is recommended every 2 years (provided the sensor is not exposed to relative humidity above 85%).

Annual calibration is required if the sensor is exposed to relative humidity above 85%.

Technical Documents

Accessories

Accessories such as mechanical and electrical fittings are available on the Accessories page.

Other Information

Part Numbers for 16 bar flow sensor, R-Thread Connection: FLF110001, FLF120001, FLF130001, FLF140001, FLF150001, FLF160001, FLF110011, FLF120011, FLF130011, FLF140011, FLF150011, FLF160011, FLF111001, FLF121001, FLF131001, FLF141001, FLF151001, FLF161001, FLF111011, FLF121011, FLF131011, FLF141011, FLF151011, FLF161011

Part Numbers for 40 bar flow sensor, R-Thread Connection: FLF210001, FLF220001, FLF230001, FLF240001, FLF250001, FLF260001, FLF210011, FLF220011, FLF230011, FLF240011, FLF250011, FLF260011, FLF211001, FLF221001, FLF231001, FLF241001, FLF251001, FLF261001, FLF211011, FLF221011, FLF231011, FLF241011, FLF251011, FLF261011

Please refer to our Terms and Conditions of Sale.